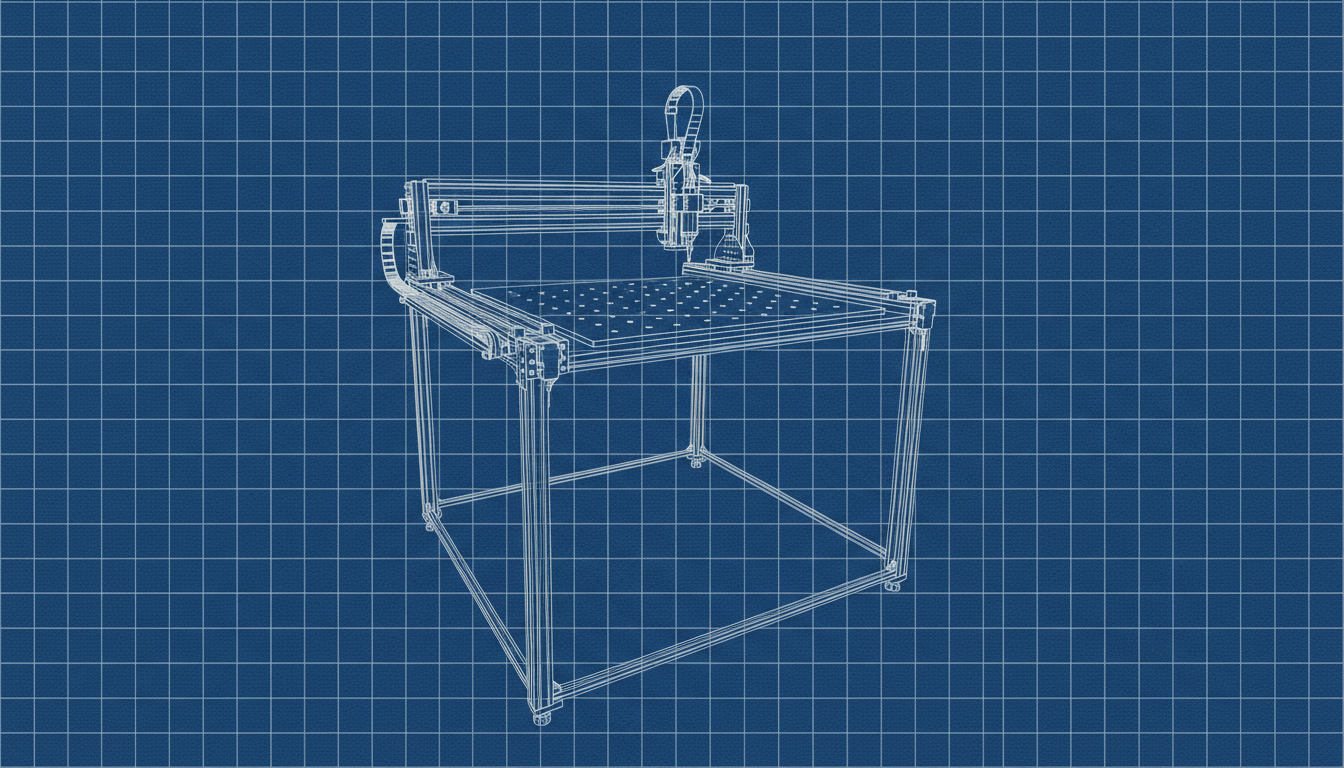

TopsCNC Heavy Metal

✍️ Topsie

📅 18 April 2022

👀 26100 vues

❤️ 172 likes

🔒 Log in to view and download STL files for this design.

Log inList of components

3D printing parts

| Nom | Qté | Notes |

|---|---|---|

| drag_chain_rail_holder_claps.stl | 7 | |

| drag_chain_rail_holder_X.stl | 3 | |

| drag_chain_rail_holder_Y.stl | 4 | |

| dragchain.stl | / | |

| dragchain_claps.stl | / | |

| Dragchain_connector_X_to_Z.stl | 1 | |

| Dragchain_support_x_to_y.stl | 1 | |

| End_bearing_holder_5mm_(X).stl | 1 | |

| End_bearing_holder_6mm_(Y).stl | 2 | |

| End_bearing_holder_part2.stl | 3 | |

| End_dragchain_female.stl | 2 | |

| End_dragchain_male.stl | 2 | |

| End_Z_bearing_holder_part1.stl | 1 | |

| End_Z_bearing_holder_part2.stl | 1 | |

| Nema23_cover_part1.stl | 4 | |

| Nema23_cover_part2.stl | 4 | |

| Nema23_Holder_Bearing_Spacer.stl | 4 | |

| Nema23_spacer_(if needed).stl | / | |

| Wheel_foot.stl (optional if you are not making the table) | 4 | |

| X_kart_to_ZAxis_connector.stl | 2 | |

| XY_Nema23_holder_part1.stl | 3 | |

| XY_Nema23_holder_part2.stl | 3 | |

| Y_kart.stl | 2 | |

| Z_kart.stl | 1 | |

| Z_Nema23_holder_part1.stl | 1 | |

| Z_Nema23_holder_part2.stl | 1 | |

| Z_Nema23_holder_part3.stl | 1 | |

| ZKart_end_dragchain.stl | 1 |

Material to buy

| Nom | Qté | Notes |

|---|---|---|

| Aluminum Profile 6060 1000mm (4 table legs, optional if you make your own table) | 4 | |

| Aluminum Profile 3030 1500mm (junction between the 4 legs of the table, optional if you make your own table) | 4 | |

| Aluminum Profile 3060 1620mm (frame) | 6 | |

| Aluminum Profile 3030 1620mm (sacrificial support) | 5 | |

| Aluminum Profile 6060 1620mm (X axis) | 2 | |

| Aluminum Profile 3060 240mm (junction axis Y / axis X) | 2 | |

| Aluminum Profile 3060 325mm (junction axis Y / axis X) | 4 | |

| Aluminum Profile 6060 145mm (junction axis Y / axis X) | 2 | |

| Aluminum Profile 30120 450mm (Axis Z) | 1 | |

| Linear rail HGR20 1500mm | 6 | |

| Linear rail HGR20 450mm | 2 | |

| Sliding block HGH20CA | 16 | |

| SFU1605 1500mm | 3 | |

| SFU1605 450mm | 1 | |

| Nema23 4.2A 3Nm + Motor drivers | 4 | |

| Aluminum Angle 6060 | 8 | |

| Aluminum Square 3030 | 40 | |

| Perforated plate 60x120 (8 holes of 6mm) | 10 | |

| Perforated plate 30x90 (3 holes of 6mm) | 10 | |

| 90° corner perforated plate 120x120 (12 holes of 6mm) | 4 | |

| Broach 2.2kW / 1.5kW + VFD | 1 | |

| Control electronics (Arduino) | 1 |

For the screws, it's complicated to say, it will depend on your components. Here is what I have used approximately.

Fasteners

| Nom | Qté | Notes |

|---|---|---|

| M5 x10mm | approx 100 | |

| M5 x18mm | approx 400 | |

| M5 x50mm | approx 20 | |

| M6 x16mm | approx 50 | |

| M5 T-nut for groove | approx 500 |

Make sure to get T-nuts that match your aluminum profiles! For my part, I took 6060 l-type profiles with a 6 mm groove, and nuts for grooves with a retaining ball for a 6 mm groove.

I haven't done the exact calculation, 500 T-nuts seems like a lot but it goes very quickly when you put 1 in each hole in the HGR20.

Count on a good 4 kg of plastic for all the parts (without the drag chains, 5 kg with).

I use a 2.2 kW liquid-cooled spindle with its VFD. You can use an air-cooled spindle or a smaller spindle (1.5 kW), but avoid the Makita on this type of machine, it's a shame.

On this machine, I'm still on Arduino. I've integrated a 5V to 10V PWM converter to control the VFD via GRBL.